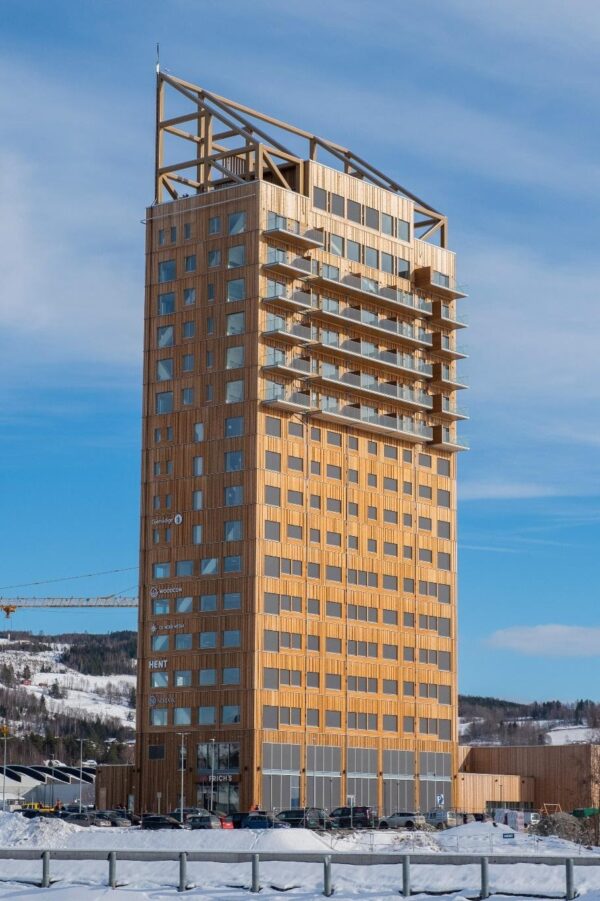

The 18 story Mjøstårnet building in Brumunddal, Norway, is built entirely of Cross Laminated Timber – including the elevator shafts. The building includes a swimming pool and communal areas.

Return to the Future: Building with one of our Oldest and Healthiest Materials – Timber

While the car industry has been forced to almost totally reinvent itself in the light of new understandings and the need to prevent catastrophic climate shifts, the construction industry has, so far, been allowed to remain in an era that began in the 1880s, i.e. the era of concrete and steel. The production of concrete and steel are, in fact, two of the main contributors to CO2 emissions. Indeed, concrete production produces a full 8% of global CO2 emissions. Steel production accounts for another 4%. Construction in general accounts for up to 50% of all greenhouse gas emissions, so clearly finding a way to get that figure down is of the highest priority.

While governments have been slow to turn their attention to the construction industry, there are people within the industry itself who are not waiting to be forced to change. Over the last two decades, intensive research has been carried out to find more eco-friendly building materials that can do the job not only as well as concrete and steel – but better and more cost-efficient. There will always be special applications that will require concrete and steel – such as large span bridges and underground works – but it is rapidly becoming unacceptable that our hospitals, schools and public housing are continuing to use materials that are doing so much damage to the environment, while new and highly eco-friendly materials are available.

One of the most successful of the new breed of building materials is Cross Laminated Timber (CLT). Anyone who has ever walked into a timber building will have immediately noticed the special energy that the wood itself imparts. One’s spirit it immediately uplifted, the air is light, there is a feeling of lightness and wellbeing. There is an urge to touch the timber walls, run one’s fingers along the edges and details as one would with a beautiful piece of furniture. A timber building is a real event. It always creates a sense of occasion and a sense of natural belonging. If patients in our hospitals could benefit from such an invigorating atmosphere, surely their recuperation would be shorter and more pleasurable. If our public housing was built of timber, surely there would be a more immediate sense of belonging and wholeness, and the social isolation and loneliness that drab and heavy buildings of concrete often propagate would give way to a more human dispensation.

Communal dining area in the Mjøstårnet building.

So, what actually is Cross Laminated Timber? And what are the practical benefits of CLT?

CLT is an engineered timber, formed by glueing together sawn planks of solid wood in layers, with each layer having the orientation of its grain at right angles to the grain of the previous layer. This disposition gives CLT its tremendous in-plane strength, which is much greater than unmodified timber.

CLT can be manufactured from softwood or hardwood. In the UK, panels of 8 ft. by 36 ft. are typically used – but the only constraint on the size of the panels is what can be transported by road. There is no constraint on the depth of the panels.

The panels are usually manufactured and cut in the same factory to the architect’s specification for any given project, then transported to the site by truck and lifted into place by crane.

A crane lifts a factory finished CLT wall panel and workers ease it into position. It will be fixed to the steel brackets shown with screws.

The CLT panels are set in place as structural load-bearing systems, or for select elements such as floors, walls, or roofs. Very little on-site waste is left. (1)

So, what are the benefits of using Cross Laminated Timber?

Benefit 1 – Sustainability

As trees grow, they remove CO2 from the atmosphere and release oxygen. The carbon is stored or “sequestered” within the wood itself. The carbon is ‘locked-in’ and remains stored within the manufactured timber product during its lifetime.

Using engineered timber products to construct buildings in lieu of traditional building materials will reduce CO2:

-

- One meter cubed of CLT panels will remove approximately one tonne of CO2 from the atmosphere during the growth of the trees they’re made from.

- The production of Portland Cement results in around 870kg of CO2 emissions per tonne of cement. (2)

- On average for 2017, 1.83 tonnes of CO2 were emitted for every tonne of steel produced. (3)

Cross Laminated Timber panels can be produced using low-tech, comparatively low energy, minimal freshwater and low waste manufacturing processes with timber sourced from sustainably managed forests.

Benefit 2 – Structural Capability

Cross Laminated Timber can be used for all elements of a building’s superstructure (walls, floor, roof) or within hybrid concrete, steel and timber structures. The high in-plane stiffness of CLT panels provides significant robustness and can be used for deep beams and cantilevers.

Benefit 3 – Construction Process

Cross Laminated Timber is ideally suited to so-called Modern Methods of Construction (MMC), particularly Offsite Modular Construction, where buildings are constructed in modules in a factory and then transported to the building site by road.

Due to the high precision of the factory cut panels, airtightness can be achieved through the use of pre-compressed foam and/or vapour permeable tape across joints.

As crane-lifted CLT panels quickly provide a dry, weatherproof environment, applying internal finishes and installing services can start soon after the superstructure works. Indeed, factory finishes are often chosen so that there are little or no wet trades on-site at all (plastering and painting).

As the panels are prefabricated offsite there is minimal waste on-site and the construction process is quiet and clean with much less equipment needed compared to traditional building methods.

A beautiful social housing project has been completed in Stockholm using CLT. It’s called “79 & Park” and is designed to fit in with the landscape as if it were a natural hill. The many rooftops each have their own green roof, where residents can grow their own vegetables and flowers.

Benefit 4 – Cost Savings

A building superstructure (the building above the foundations) constructed entirely of CLT will still require concrete and steel foundations but will be as little as a quarter the weight of a concrete and steel superstructure. This means that smaller foundations are required – thus using less costly concrete and steel.

Adding additional floors to an already existing concrete and steel building becomes much more feasible with CLT, as the already existing foundations and superstructure are likely to be able to bear the lightweight CLT structure with little or no additional support.

In theory, at least, the fact that the CLT building elements are cut in the factory should mean significant time saving and thus cost-saving. However, this industry is in its infancy in Ireland and teething problems are to be expected. Meticulous project management will be the key to success.

Projected reduction in the overall cost of construction is based on:

- Less weight in the overall structure, thus needing less concrete and steel in the foundations.

- The high degree of accuracy afforded by the factory cutting process ensures that panels of precise dimensions with exact structural openings will be delivered to site.

- Since the panels can be delivered to site finished, less on-site wet trades are needed, i.e. plastering and painting.

Communal facilities at 79 & Park include a preschool and daycare for dogs.

Benefit 5 – Design Flexibility

The lightness and strength of CLT panels, and the accuracy with which they can be cut, offer greatly enhanced design flexibility and architectural freedom. To date, over 300 CLT buildings have been built in the UK alone, across a wide range of sectors. As awareness and acceptance of solid timber construction grows over the coming years, new innovations, applications, developments and benefits will emerge.

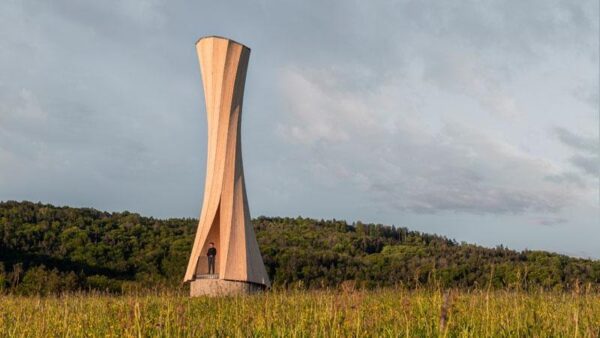

A spectacular example of this emerging innovation is research conducted during 2019 at the University of Stuttgart under the direction of Professor Achim Menges, who has long been a leading advocate of timber construction. His team showed how moisture levels in CLT can be varied using Finite Elements Analysis so that when the timber is dried it self-curves into pre-programmed shapes. This is possible as CLT is constructed of multiple layers, and each layer can have a different moisture level and so will dry at a different rate. (4) Of course, wood has been curved by the furniture industry for centuries, but these methods require large machinery and use large amounts of energy. Curving large expanses of timber is almost impossible. Using the self-curving characteristics of CLT, researchers were able to curve 45 meter long panels – and construct a tower from them to show the stability and beauty of the process. (5) Having a system of large scale self-curving timber is a revelation for the construction industry. There are many applications were curved walls would be highly desirable, but up until now the cost and difficulty of building accurate curved walls has often forced architects to settle for straight walls.

Urbach Tower, Germany, is constructed of just twelve 45m panels of self-curving CLT. (5)

Benefit 6 – Fire Performance and Blast Testing

A century ago, a typical way to build a firewall was to nail two by fours or two by sixes together and make a massive solid timber wall. The natural process of charring during a fire actually serves to protect the structural integrity of the timber.

An advantage of timber is that it burns at a constant rate, regardless of changes in heat level, so its behaviour in a fire is actually more predictable than concrete and steel. It’s possible to calculate precisely how much of the timber will be consumed after a given time.

In the UK, a system of compartmentation is used, with a one-hour fire separation between each apartment and a two-hour separation on the lobby and the elevator shaft.

Blast testing has revealed impressive performance, and where there is a requirement for blast resistance, cost savings can be realized using CLT.

A full discussion of CLT fire rating can be found from page 110 of The Case For Tall Wood Buildings. (1)

Benefit 7 – Health and Safety

Since much more of the work is carried out in a controlled factory environment, health and safety for workers can be greatly improved.

Benefit 8 – Acoustic Performance

Wood is a sound absorptive material and offers excellent natural sound-damping. As a result, wood has long been specified for applications requiring noise mitigation, such as in libraries. Other sound-absorbing materials, such as mineral wool, glass fibre, cellulose fibre, open-cell foams, and acoustical tiles, along with air cavities can be used to enhance noise control in any CLT building.

Benefit 9 – Thermal Resistance (R-Value)

Heat retention is one of the areas in which CLT excels. As the panels are factory cut, they are very airtight, and this airtightness is enhanced by using airtightness membranes and tapes.

A softwood CLT gives about 1.4 R / inch, so an 8-inch wall gives approximately 11.2 R and this can be doubled by using a wood fibre insulation on the exterior, or interior insulation. Of course, a 16-inch wall will have no need for extra insulation at all.

Beautiful cottages on Mull, Scotland, have been built with CLT. Incredibly, they need no central heating.

Interiors of the CLT cottages on Mull. “The emphasis of the project was on achieving an affordable and energy-efficient building.” (6)

Benefit 10 – Healthcare and Wellness

In a review of the academic literature on the use of wood in buildings, including hospitals and clinics, Burnard and Kutner found that “To date, studies examining the psychophysiological effects of wood use in interiors have revealed reduced autonomic stress responses when compared to rooms without and with less wood. Therefore, by increasing wood use in design paradigms seeking to bring the positive health benefits of nature into the built environment, like restorative environmental design, building designers may improve the well-being of building occupants.” (7)

Maggie’s Oldham, England, is a clinic which cares for cancer patients. The building is constructed of American tulipwood CLT. Even the door handles are made of wood so as not to hurt the sensitive hands of the patients.

As mentioned above, a building of wood offers a delightful antidote to the cold institutional feeling that most healthcare facilities today will wish to avoid. As well as the patients feeling better in a timber building, staff also feel better and the literature suggests that they will be happier and less subject to sick days. This will be all the more so if a green roof can be installed on the timber building. (8) In addition to its cost and aesthetic benefits, wood’s ability to dampen sound makes it well-suited for spaces where privacy and quietness are required. Wood can also help manage humidity levels by absorbing and releasing moisture found in the indoor air, reducing stress on the building’s heating, ventilation and air conditioning systems. Factory finished wood surfaces are also very easy to clean and do not discolour as easily as paint does.

Interior view of Maggie’s Oldham. To enhance the healing presence of wood, a tree grows up through the centre of the building.

Conclusions

Wood is an abundant natural material, which has been used to house our people since the dawn of time. It breaths in carbon dioxide, and breaths out fresh oxygen. If we give it the respect it is due, we can replant our planet with forests and responsibly harvest enough timber to solve the unimaginable global housing crisis that we have allowed to worsen and worsen every year without respite.

Cross Laminated Timber is perhaps the best chance architects and construction engineers have for reducing greenhouse gas emissions to tolerable levels and to give our people the homes, schools, hospitals and clinics they need and deserve.

The era of building everything from concrete and steel is coming to an end. A more aware public will demand a more self-aware construction industry. As with the car industry, men and women in the construction industry are making great strides in achieving new advances in methods and materials. At present, they are the minority. But that will change. Wood is perhaps our oldest and most beautiful building material, and it’s staging a magnificent and unexpected come back. It is giving us cause for optimism.

References

- https://cwc.ca/wp-content/uploads/publications-Tall-Wood.pdf

- “The cement industry’s role in climate change,” Dr Robert McCaffrey, Global Cement & Lime Magazine

- https://www.worldsteel.org/publications/position-papers/steel-s-contribution-to-a-low-carbon-future.html

- https://advances.sciencemag.org/content/5/9/eaax1311

- https://www.contemporist.com/urbach-tower/

- https://passivehouseplus.ie/magazine/new-build/scottish-isle-eco-cottages-need-no-central-heating

- https://link.springer.com/article/10.1007/s00226-015-0747-3

- https://www.worldgbc.org/sites/default/files/compressed_WorldGBC_Health_Wellbeing__Productivity_Full_Report_Dbl_Med_Res_Feb_2015.pdf